Air Conditioning

In compliance with the (F Gas) European Commission Regulation 842/2006, as from 4th July 2010 all technicians working on vehicle air conditioning systems need to hold the City and Guilds 5101/301 Refrigerant Handling Certificate – clearly this is held by AC autoworks.

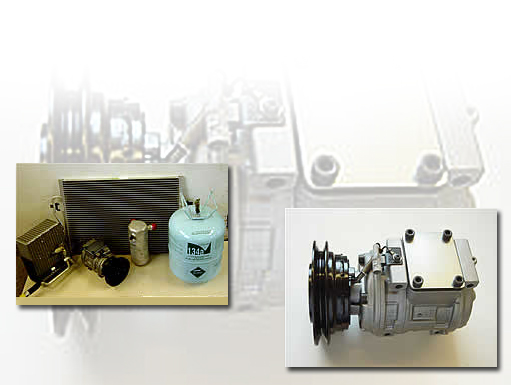

For those who know what they are looking for we provide the comprehensive list at the left.

If the list makes no sense to you then rest assured we can make your air conditioning ‘happy’ – whatever is wrong with it.

A simple tip

During the winter, periodically run your air conditioning. This will reduce the build up of bacteria. It’s the bacteria that provide a nasty smell.

Recharging Refrigerant

Our standard recharge includes:

- Check system standing and running pressures

- Degas and measure amount recovered from system

- Visually check system including:

Compressor condition for security and seizure, drive belt condition

Condenser condition is clean and dry. Condenser fan operating

Evaporator condition for leaks and cleanliness.

Check condition of pollen filter (if fitted).

Check water condensation drain tube is clean and free

Check all hoses and pipes, electrical wiring and switches - Pressure test system using OFN (oxygen free nitrogen)

- Evacuate system of air and moisture

- Charge system with correct type & amount of refrigerant,

add dye and correct type of pag or ester oil - Check running pressures, check condenser fan operation and

vent temperatures inside vehicle - Finally leak check system using electronic leak detector

Fault Diagnosis

At AC autoworks we are well qualified to carry out extensive diagnostic work into all your vehicle air conditioning problems. Occasionally the fault may lie outside of the air conditioning system.

If this is the case, we also have the expertise to diagnose electrical and mechanical faults and rectify them as necessary.

Our diagnostic equipment enables us to quickly and efficiently pin point the fault (or faults) within your system. We can select the electronic schema for your vehicle to dial into the system employed by your vehicle.

We select your particular model, and system and pin point the first fault.

We continue until all faults have been identified and rectified

Component Replacement

Most air conditioning components can be replaced or repaired on site by our engineers. However, more complex work would have to be carried out at the workshop.

10 Point Service

Our Ten Point Air Conditioning Service includes:

- Check system standing and running pressures

- Check vent temperatures and all air conditioning controls inside vehicle

- Degas and measure amount recovered from system

- Visually check system including:

Compressor condition for security and seizure, drive belt condition

Condenser condition is clean and dry. Condenser fan operating

Evaporator condition for leaks and cleanliness. Check and/or replace pollen filter.

Check water condensation drain tube is clean and free

Check all hoses and pipes, electrical wiring and switches - Replace receiver drier or accumulator and ‘O’ rings

- Pressure test system using OFN (oxygen free nitrogen)

- Evacuate system of air and moisture using vacuum pump for 30 mins

- Charge system with correct type & amount of refrigerant, add dye and correct type of pag or ester oil

- Check running pressures, check condenser fan operation and vent temperatures inside vehicle

- Finally leak check system using electronic leak detector

Prices from £99

Leak Detection

We use three methods of leak detection

- Electronic leak detection

using high sensitivity equipment for all refrigerants - Oxygen free nitrogen pressure testing

This is an environmentally friendly way of checking for leaks before charging the system - Ultra violet light leak detection

With the use of dye injected into the system, hard to find leaks can be detected.

Odour Elimination

When the A/C system is not used for a long period of time ie, winter, the system is ripe for bacteria to grow, so when the system is switched on in the spring or summer it can emit unpleasant odours from the build up of bacteria formed on the evaporator. AC autoworks advise that you run the system in the winter period to stop this build up of bacteria on the evaporator.

On inspection of the ventilation system, the pollen filter is checked, the system is then run to check for bacteria odours, electrical burning smells or cigarette smoke. If the bacteria odour is smelt the evaporator needs cleaning. The bacterial and fungicidal cleaner incorporating disinfectant is sprayed onto the evaporator unit directly and is left for 20 mins to penetrate and clean the surface area of the unit. The system is then run for 10 mins to dry the evaporator and check for smells.

Pipes and Hoses – making and repairing

We have the facility to make & repair rubber hoses and aluminium pipe work – providing a cost effective alternative to pipe/hose replacement. This work can often be done on site.

New HFO1234yf Refrigerant

Over the next few years car manufacturers are being forced to change the refrigerant used in car air conditioning systems.

The EU has decided that the refrigerant used over the last 20 years is less environmentally friendly than HFO1234 yf, which has a global warming potential of 4, compared to 1300 for R134a, and has a life span of 11 days compared with 13 years for R134a if released into the atmosphere.

Re-designed cars and all new cars from 2017 must use the new refrigerant, however most car manufacturers have been using the new refrigerant since the beginning of 2014.

The refrigerant is mildly flammable and it may be necessary to have it removed even if the system is not damaged e.g. before going into a low bake oven for spraying.

AC Autoworks are the first R1234yf specialists in the area.

We are fully skilled and equipped to work on any vehicle, either in our own workshop or mobile.

The price for the new refrigerant will be considerably higher than R134a. Because of the high cost of the refrigerant and the varying amounts used in different makes/ model of car we will initially be quoting each recharge individually.

Because of the higher refrigerant costs we will also insist on a nitrogen pressure leak test before recharging.